REQUEST A SECURE QUOTE

Submit a request and a tubular parts fabrication expert will respond.

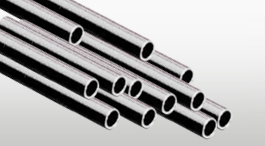

Tube Cutting

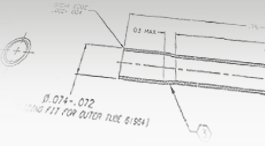

We cut tube lengths starting from from 0.020″ ±0.001″, burr free, with little OD/ID distortion. Cut tubes from all workable alloys, up to billions of parts. Forming & finishing available.

Tube Cutting Services

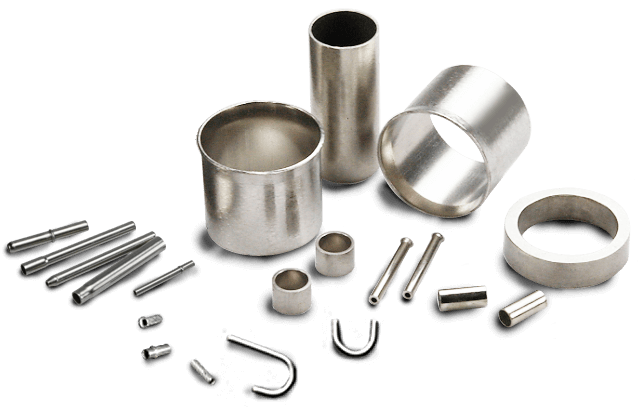

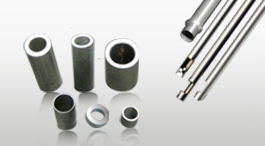

Tubular Part Fabrication

Cutting, bending, end forming and finishing for small tubes sized 0.022″ to 0.625″, with lengths as short as 0.020″ and tolerances to ±0.001″. Tubes made from all workable alloys.

Tube Forming Services

Electro-Machining

Electrochemical saw cutting (ECM), electrical discharge machining (EDM), wire erosion, and electrochemical grinding (ECG) are available for small tubular parts.

Electro-Machining Services

Tube Bending

Single radius bends as tight as 3 Xs the OD center line radius for small tubing and hypodermic tubes sized 0.020″ to 0.375″. Bending is integrated into the tube fabrication process.

Tube Bending Services

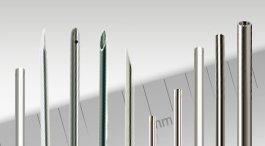

Hypodermic Tubing

Stainless steel hypodermic tubing, 3 GA to 24 GA, precision-cut and machined to your specifications. Standard & custom gauge hypotubes available.

Four Slide Engineering

We’ve been cutting and forming small tubular parts for the Electronics, Medical, Aerospace, Automotive, HVAC, Energy/Nuclear and other sectors since 1985. Try our helpful & experienced Engineering Support.

Family Owned and Made in the U.S.A.

Family owned and operated for over 30 years, Four Slide Products is proud to fabricate precision cut tubular parts in the USA.

Precision Tube Fabricating

& Bending Services

We manufacture precision cut tubular parts. Our specialized tube cutting machines eliminate material waste, saving you up to 50% on material costs. Our unique multi-stage tube cutting and bending machines achieve most tube end forming during the tube cut-off process, reducing handling costs. We cut, bend, end form, and finish tubing to precision specifications, from hundreds to billions of parts. Tube end formations include flare, flange, bulge, single or double ID radius, flatten and pierce, rounded end, reduced end or swaged end, and more. We also offer secondary operations that include axial or diamond knurl, corseted or grooved, and more.

We finish parts by tumbling, deburring, coating, ultrasonic, polish, anneal, plate, Harperize, passivate, grit, sand, or bead blasting. We source materials or work with yours including Stainless Steel, Copper, Brass, Titanium, Inconel®, Aluminum, Nickel, Monel®, Nichrome, Gold, Platinum, 52 Alloy, 42 Alloy, Rodar/Kovar®, Nickel/Silver, Cupro Nickel, Bronze, Phos/Bronze, Silver, Hastelloy®, Invar®, Red Brass, Tantalum, Zirconium, and any workable alloy.