ELECTRO-CHEMICAL CUTTING, MACHINING & GRINDING

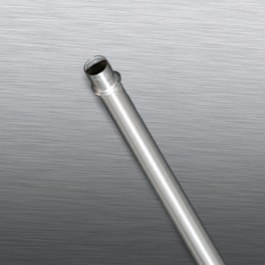

Electrochemical cutting is recommended for most parts over 3 inches in length. It also produces a superior finish on critical parts, with no distortion or thermal stress. We can provide most end formations as secondary operations.

- ECM/EDM benefits available for cut-to-length tubing

- Cut out achieved without mechanical or thermal stress

- Reverse plating process removes burrs

- Precision tube fabricating & bending services – up to billions of parts

REQUEST A

SECURE QUOTE

Our tube fabrication & cutting experts are ready to create your quote

Four Slide Products provided accurate delivery information not only in the quoting stage but through the production phase.

Duane D. Riha,

Legacy Technologies, Inc.

EDM: Wire Erosion Cutting

Electrical discharge machining (EDM), also called spark machining, spark eroding, burning, die sinking or wire erosion, is primarily used for hard metals or electrically conductive metals that are difficult to machine in other ways. EDM can cut intricate contours and cavities.

Let's Get Started!You can submit drawings for a quote or contact us about your project needs or call us now at 610-746-0688

ECC Electrochemical Cutting – Electrochemical Saw

Electrochemical cutting or electrochemical saw cutting is a form of electrochemical grinding (ECG) utilizing a cutting wheel in place of an abrasive grinding wheel. Most tubular parts over 3 inches in length are cut with an electrochemical saw. Cut parts are automatically deburred by the reverse plating (de-plating) process.

Let's Get Started!You can submit drawings for a quote or contact us about your project needs or call us now at 610-746-0688

ECG: Electrochemical Grinding

Electrochemical grinding (ECG) uses electrical current and an abrasive wheel to cut without heat stress, burrs or mechanical distortions. Oxidation stops the cutting. Then an abrasive grinding wheel removes the metal oxide, restarting cutting. Cathode-anode current flow, conductivity and electrochemical reactivity determine the ECG machining rate.

Let's Get Started!You can submit drawings for a quote or contact us about your project needs or call us now at 610-746-0688

ECM: Electrochemical Machining

Electrochemical Machining (ECM) or reverse electroplating utilizes an electrically conductive work piece as an anode with a conductive tool as a cathode in an electrical circuit. As the gap between tool and metal decreases, current flows and dissolves the workpiece material. Electrolytic fluid flushes material as the tool advances.

Let's Get Started!You can submit drawings for a quote or contact us about your project needs or call us now at 610-746-0688

Four Slide Products Inc.

A Custom Manufacturer of Precision Cut Tubular Parts

Helpful electrochemical machining (ECM), electrochemical grinding (ECG), and electrical discharge machining (EDM) information resources include: Manufacturing Processes Reference Guide